NCCR / Performance Integrated Digitally Fabricated Components

Duration /

2018–2022

Funding /

Swiss National Science Foundation

A/S Team /

G. Lydon, I. Hischier, A. Schlueter

Demonstrators /

NEST Hilo

Key Partners /

Block Research Group (ETZ Zurich)

Chair of Digital Building Technologies (ETH Zurich)

Selected Publications /

1 / G. P. Lydon, S. Caranovic, I. Hischier, A. Schlueter. "Coupled simulation of thermally active building systems to support a digital twin," in: Energy and Buildings 202 (2019): 109298. DOI Research Collection

2 / G. P. Lydon, J. Hofer, B. Svetozarevic, Z. Nagy, A. Schlueter. "Coupling energy systems with lightweight structures for a net plus energy building," in: Applied Energy 189 (2017): 310-326. DOI Research Collection

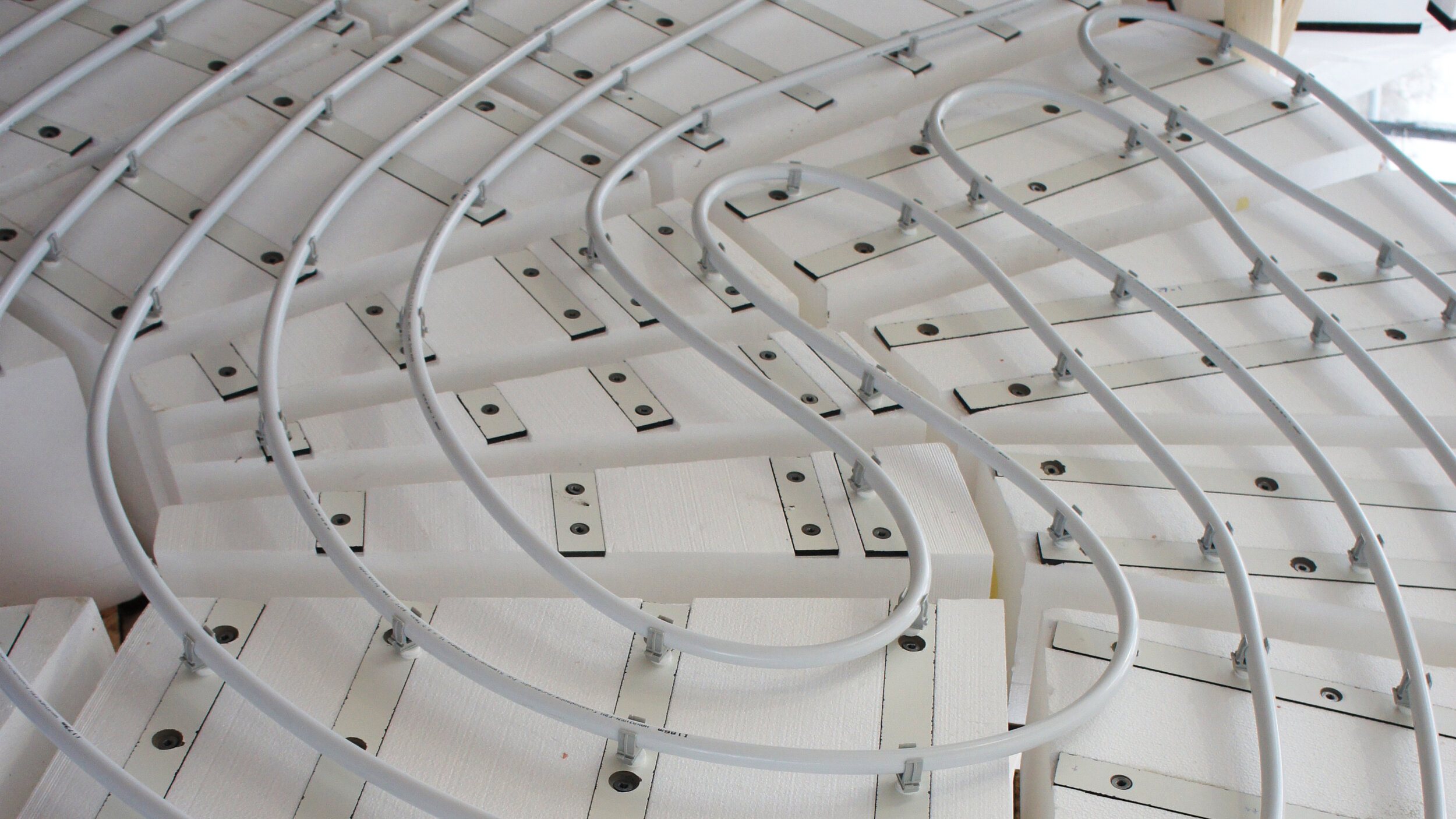

Thermally active building systems (TABS) integrate hydronic pipework within a structural element to create a radiant panel. By activating large surfaces, heating and cooling can be provided with a supply medium that is near room temperature, which is compatible with renewable geothermal sources. During the operation phase of the building, this approach generates less equipment noise and provides an improved vertical air temperature distribution compared to air-based space conditioning systems. Traditionally, TABS are implemented in heavyweight concrete structures. The density, heat capacity and thermal conductivity of concrete provide for heat storage and thermal inertia. However, a massive structural frame requires more time to reach a steady-state operating condition and an increase in thermal losses to the structural materials in the heating case.

A/S has worked on overcoming these shortcomings by employing interdisciplinary design methods and taking advantage of a lightweight structural geometry. Significant embodied and operational energy savings can be realised by using less space to perform several functions simultaneously, such as energy, architectural and structural aspects. This approach is demonstrated in the functionally integrated floor system that is part of our NEST HiLo project.

The performance of the multifunctional element is optimised using digital methods, which include high-resolution numerical modelling and additive manufacturing. Combining precise thermal simulation with the geometrical flexibility of 3D-printing results in a radiant surface that improves reaction time while retaining the benefits of thermal inertia. Additionally, one of the floors will be equipped with a custom ventilation duct that is an integral component of the 3D-printed formwork system.

The Funicular Floor demonstrator, showcasing the reduced amount of concrete and internally integrated cooling and ventilation system made possible by the 3D printed formwork © Digital Building Technologies, ETH Zurich. Andrei Jipa

Detail view of the heating coil © Digital Building Technologies, ETH Zurich. Andrei Jipa

Floor slab – design of a lightweight thermally active building system © Architecture and Building Systems, ETH Zurich

TABS placement on prototype of doubly curved roof surface © Architecture and Building Systems, ETH Zurich

Completed TABS layout © Architecture and Building Systems, ETH Zurich

Section of a doubly curved roof with integrated hydronic pipework © Architecture and Building Systems, ETH Zurich